Brakes are essential for any automotive vehicle for its functionality…

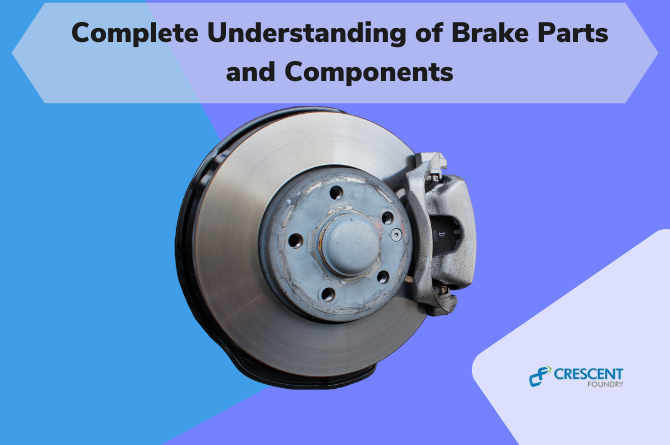

Complete Understanding of Brake Parts and Components

The automotive industry largely depends on the braking system for effective functioning. Not only the varied applications in the industry but also people using vehicles rely on well-functioning braking systems to drive, and ensure safety on the road. But do you know the components that come together to form the complete braking system? Brake parts manufacturers in India play an important role in providing the automotive industry with the essentials of the total system. Read on to know more about the major brake parts and components.

Rotors

One of the major parts of the braking system, rotors are spherical discs fastened to the wheel hub. Typically made from steel or cast iron, this component rotates with the wheel. Brake rotor suppliers in India supply rotors made of carbon and ceramic, particularly used in expensive cars.

The purpose of rotor design is to convert kinetic energy (motion) into thermal energy (heat). When you press the brakes, the master brake cylinder signals your callipers to push your brake pads tightly against the broad surface of the rotors. Since rotors are attached to the wheels, the movement is brought to a halt. Brake rotors deteriorate slightly with each application of the brakes, much like brake pads do. Rotor lifespans can range from 30,000 to 80,000 miles on average.

Rotors are designed differently, depending on their area of application.

- Plain or smooth rotors which have no holes or slots.

- Bored rotors have holes drilled into the metal surface.

- Long “slots” or lines can be seen in the metal surface of slotted rotors.

- For improved performance, drilled and slotted rotors combine the drilled holes with slots.

Brake Pads

Brake pads refer to the component of the braking system that presses on the moving rotor. These pads apply pressure to the moving rotor, causing friction and ultimately bringing an automobile to a stop.

The brake pad (in a disc braking system) engages a hydraulic line, which when pressure is applied, forces the callipers against the rotors. In order to absorb energy and heat and subsequently offer enough traction to stop the automobile, pads are positioned between the callipers and the rotors.

Brake pads are generally made of a combination of materials like resin, carbon compounds, rubber, glass or fibreglass. Although these components typically last for 50000-60000 kilometres of usage, brake pads can wear out depending on the driving conditions. It is important to know how to make brake pads last longer and for that, there are some precautions to take – like coming to a sudden halt after speeding, riding with the brakes pressed and not ensuring proper maintenance are some of the factors that can cause brake pad wear.

Sensors

Since braking involves friction, it is natural that there will be wear and tear due to the heat and kinetic energy generated. But how to understand when to get the components checked and replaced? That is why, brake parts manufacturers in India, USA, UAE, Africa recommend attaching braking systems that have sensors attached to the brake pads. Brake pad sensors alert the driver when the brake pads are too thin to effectively serve its purpose.

Without the sensors, it is likely that a metal sheet will come into contact with the in-motion rotor when the brake pads deteriorate. This will create a squealing sound as well as can be damaging to the braking components. Sensors are designed to prevent such scenarios. Sensors too eventually become worn down along with the brake pads. The car’s ABS system uses additional braking sensors to allow a car to stop quickly and even steer while stopping.

Callipers

Calliper assembly in a braking system refers to the clamp-like component that sits on the rotor. The function of callipers is to host the hydraulic pistons and brake pads. When brakes are applied, the hydraulic fluid presses the pistons towards the brake pad. As a result, brake pads clash against the moving rotors, causing the vehicle to stop.

Brake callipers suppliers in India offer two variants of callipers: floating (sliding) and fixed. Floating callipers only have pistons on one side and “float” on the rotor. For floating callipers, when the driver applies the brakes, the piston presses the brake pad onto the rotor on one side. This causes the calliper to slide up and make contact with the rotor. In cases where fixed callipers are used, pistons push brake pads from both sides onto the rotor to stop it.

Together these components contribute to efficient functioning of braking systems. Before choosing braking parts, it is essential to choose from the finest manufacturers in the industry. The best (drum) braking systems put together by the top brake drum manufacturers in India. With superb quality raw materials and use of advanced machinery, braking components from manufacturers like Crescent Foundry are best-suited for automotive applications.